CHIMNEY FLUE INSTALLATION - RECENT FIRE SAFETY RULES

Edita Gruiniūtė

Chimney flue installation - one of the most responsible stages of building construction. Leaking, poorly equipped and made from unsuitable materials, chimney flues may at any time cause poisoning or fire accident. Therefore, chimney installation requires sufficient practical and theoretical knowledge of constructions requirements and installation features.

Basic installation rules

Since May 1, 2014, new fire safety rules regarding new heating systems using solid fuel comes into effect. They must be followed in preparation for the design and construction of new buildings, partial reconstruction of buildings, or when their intended use is changed. Also, during the repair of the buildings by installing or replacing heating systems using solid fuel. Of course, if you want the chimney flue for optimum performance and safe usage.

To avoid chimney flue installation problems, much attention should be paid to the correct installation. The rules provide that the chimney flues must be installed by following the manufacturer's technical information or constructed from solid bricks. In this case, heat-resistant mortars should be used for the walls and shaped chimney flue wall should be at least 120 mm thick.

Solid brick, except clay chimneys, will also be required to install backings to protect them against the harmful tar and acid condensates. Meanwhile, the segments of metal inserts must be connected by stainless steel rivets or special locks. By the way, it is prohibited to install uninsulated metallic single-wall chimneys.

An exhaust outlet through which the heating plants discharge combustion products must be mounted vertically. A slight tilt is allowed: chimneys cannot tilt more than 45° degrees from the vertical direction, while deviation of the upper part in the horizontal direction - not more than 1 meter.

Meanwhile, the connecting tubes of the chimney flues must be tilted in a vertical direction at an angle not bigger than 90°. The construction of the connecting chimney flue pipe walls is of solid clay bricks, they should be at least 120 mm thick, made from heat-resistant concrete and be at least 60 mm thick. Meanwhile, ceramic or cast iron walls should be thicker than 4 mm, made of the multilayer flexible metal at least L50 media type and be at least 0,1 mm thick.

The distance from flammable materials

When installing chimney flues, it is necessary to maintain a safe distance from the chimney flue to combustible materials. Appropriate construction materials should be selected. The new fire safety rules for heating systems using solid fuel provides that from bare ceramic, cast iron, concrete and metal connecting flue walls must be maintained at least 500 mm distance to combustible materials of building construction. Meanwhile, 250 mm distance is allowed if the insulated outer surface of the connecting chimney flue is thicker than 50 mm of a flame-resistant material having a maximum operating temperature greater than 600°C.

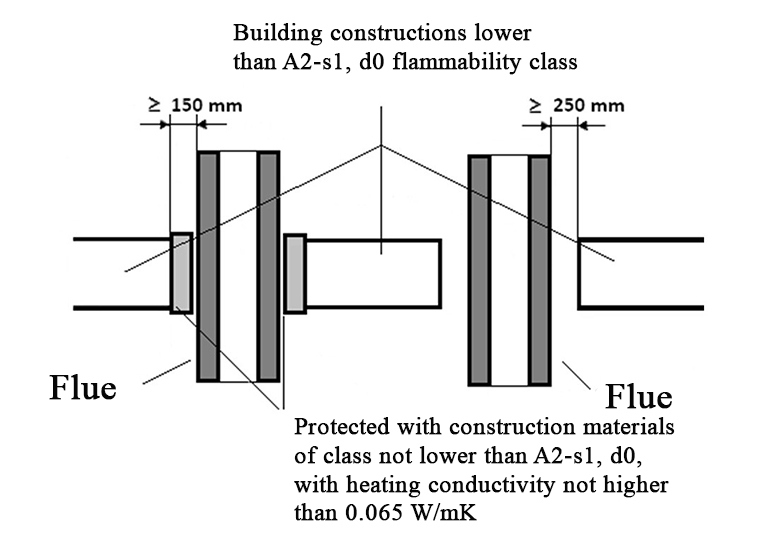

The distance from the outer surface of the chimney flue wall to the combustible materials structures shall not be less than 250 mm. 150 mm distance is allowed if the entire thickness of the structure is protected by non-combustible and heat-resistant construction products with a heat conductivity of at least 0.065 W/m•K.

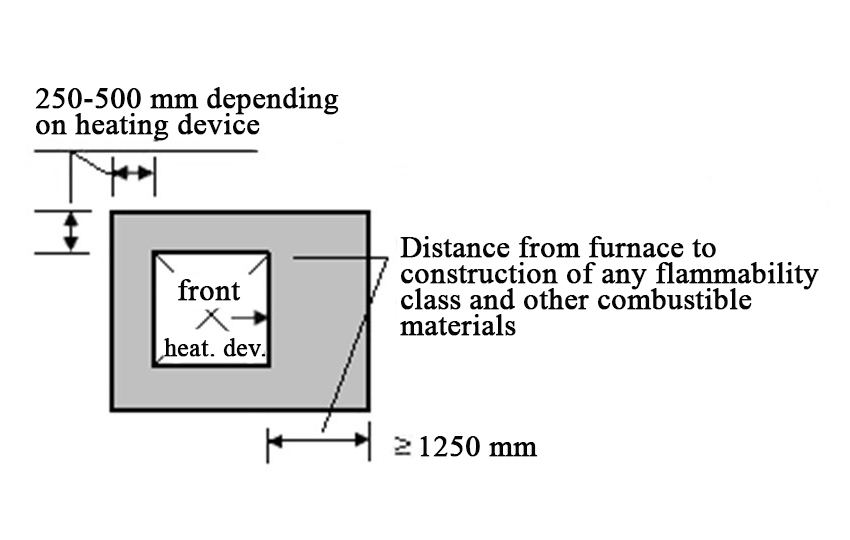

The distance between the heating device (except metal) and flammable materials building structures shall be not less than it is indicated in manufacturer's requirements, or 250 mm - from the heating device, which is intended for non-permanent space heating, 500 mm and 1000 mm - from the heating unit and the unprotected ceiling with lower than A2-s1, d0 flammability class.

The distance from the front of the firebox to building construction of any flammability and other flammable materials must be not less than 1 250 mm.

How to properly connect a heating device

Many problems may occur due to incorrect device connection to the chimney flue, using heat-sensitive sealing materials or connecting elements. Not more than two heating devices, located on the same floor, can be connected to a single chimney flue because they may not work reliably. Lower general part of the chimney must be installed from the same construction materials as the chimney itself. At least 1 m high partition, separating the connecting areas of connecting flues must be made. The height of the dividing partition must be calculated from the connecting spot of individual heating devices into the chimney flue.

If two heating devices are connected to a chimney flue from different sides, their connecting flue height difference must be not less than 600 mm. It is also important not to forget to equip heating devices with separate valves. In this case, both heating devices must belong to a single user.

If there are no valves in the connecting pipes for removal of heating equipment combustion products (dampers), then a chimney flue should be equipped with manually operated valves with a minimum of 15 mm diameter hole or their area should be 5 % smaller than chimney flue duct area.

It is necessary to take care of the ventilation openings

When installing the chimney flue, it is also important to ensure the effective operation of a ventilation system. In the case of too intensive smoke traction, it can be reduced by using traction control. To increase it, you must use dedicated mechanical fans mounted on top of a chimney flue. If the mechanical fan is installed in the lower part of the chimney flue, then it must comply to a pressure class lower than P1.

If buildings contain heating devices but air flow is not provided, then it is prohibited to install a ventilation system with forced air removal. Smoke direction into ventilation ducts, installation of ventilation grilles in smoke ducts, to merge them into ventilation channels is also prohibited. Under no circumstances, combustion products may not be removed through channels or chimney flues which are connected to gas or liquid fuel heating equipment.

Flammability of the materials used

To those preparing to repair heating equipment and purchasing building materials, it is important to check whether they are non-flammable. Information about this can always be provided by specialists or marketing consultants. Proper choice of building materials will help to avoid the risk of fire or other problems. In the construction of solid fuel heating equipment and chimney flues, installed in the external partition structures of the building only non-flammable materials must be used. The main non-combustible construction products in accordance with applicable standards are labeled with the following flammability class identifying marking

s: A1, A2 - (building products), A1FL, A2fl - (floor) BROOF (t1) - (roofs and roofing).

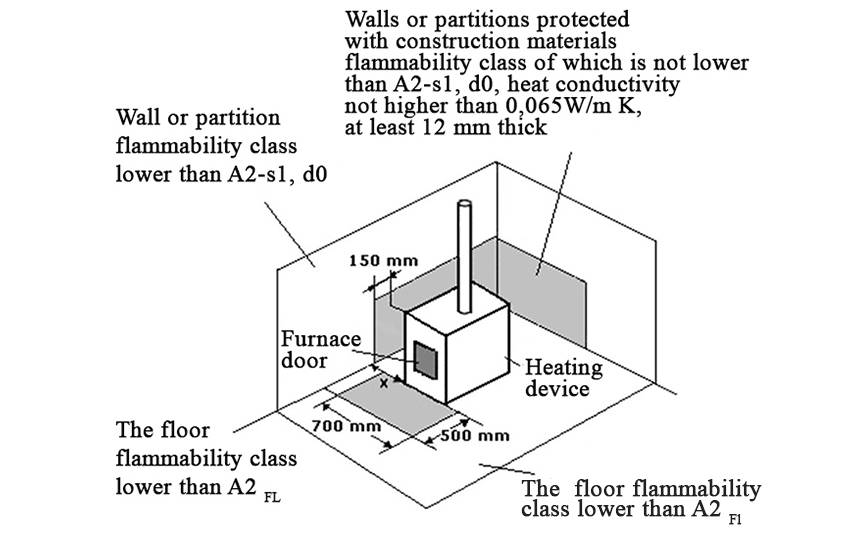

The floor under furnace doors of the heating device must be installed on A2fl flammability class products that are resistant to fire and heat. If, however, it shall be constructed of combustible materials, such floor must be covered with a non-flammable and heat resistant materials of an area at least 700 × 500 mm with a thermal conductivity not more than 0,065 W/m•K and at least 12 mm thick. Floor protection should be laid in front of the heater combustion chamber. Its length should be 150 mm larger than the outer dimensions of the heating system.

If the floor or entablature is fitted with combustible materials, the distance from the floor to the combustion chamber door, ash collectors or gas exchange channel bottom should be at least 210 mm. Meanwhile, if the entablature or floor are equipped with non-combustible materials, the combustion chamber door, ash collector or gas exchange channel bottom can be installed at floor level.

The chimney cross-section

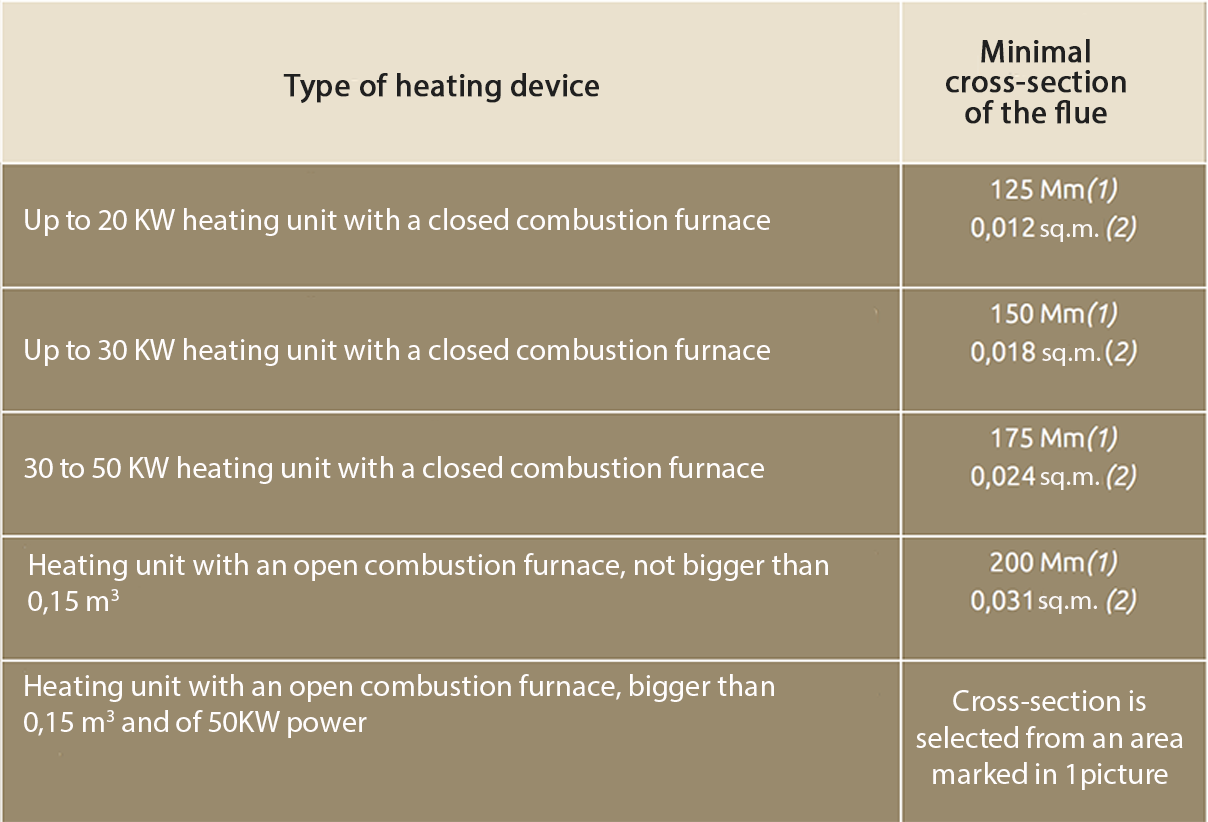

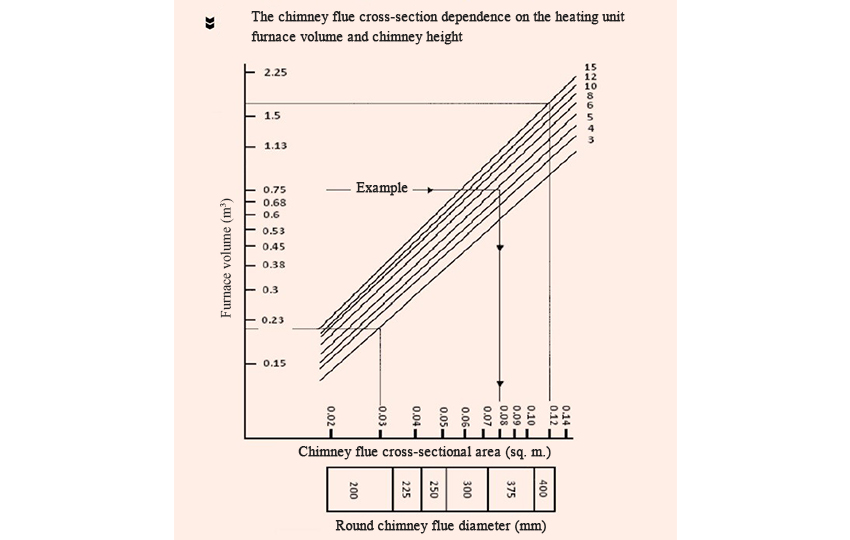

To ensure good traction, a sufficient chimney height and cross-section is necessary. Chimney flue height from furnace bottom of the heating device to the top of the chimney must be at least 3 m. Meanwhile, its cross-section should not be smaller than the cross-section of the bridging exhaust tube of combustion products of the heating device. If several heating devices are connected to the same chimney flue, its cross-section should not be less than the total sum of the cross-sectional area necessary for the heating devices. The chimney flue cross-section size must be selected according to chimney cross-section setting table and manufacturer's technical requirements to the heating device. Cross-section of the connective chimney flue should not be smaller than that of the heating device to which it is connected.

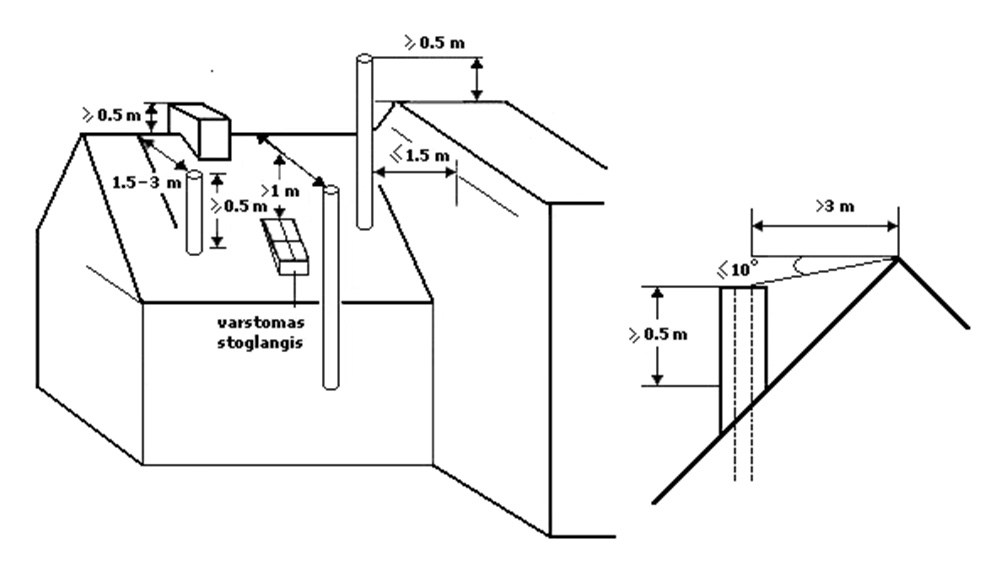

How tall chimney flue should be can be determined by the highest roof or the roof of the attached building, located less than 3 m away from the chimney flue. It must be completed not less than 1 m above the flat roof, not less than 0.5 m above the roof ridge or parapet if the distance between the chimney and the roof ridge or the parapet is less than 1.5 m. If the distance between the chimney and the roof ridge or parapet is from 1.5 to 3 m, then the chimney flue must be installed not lower than the ridge of the roof or the parapet. In cases where the chimney flue is away from the ridge more than 3 m, it is important to install it not lower than the line which goes from the 10° downward from horizontal axis down the ridge. If a distance in the horizontal projection from the chimney flue to the window is 3m or less, then it should be installed not lower than 1 m above the opening windows. In buildings with roofs attributed to FROOF (T1) flammability class, the top of the chimney flue should be 0.5 m.

There must be a cleaning possibility provided for chimney and connecting flues longer than 1000 mm by the installation of cleaning and inspection openings for that purpose. The cleanup door must be airtight, made of heat-resistant materials with flammability class not lower than A1.

To protect brick chimneys from precipitation, the easily removable roof should be mounted on them. It cannot be installed too low or otherwise restrict the natural movement of the smoke. The distance from the top of the chimney flue to the roof must at least have the diameter of a flue channel or its longest side. In this case, the roofing must be heat and fire-resistant (BROOF (t1) flammability class). Chimney flues should themselves have spark arrestors: fire-resistant grids made with apertures not bigger than 15 × 15 mm.

(1) Round chimney flue diameter.

(2) Square chimney flue minimum cross-sectional area.

Fig. 1 The chimney flue cross-section dependence on the heating unit furnace volume and chimney height

Fig. 2 Chimney flue layout principle

Fig. 3 The principle of chimney flue connection to the heating system principle

Fig. 4 The principle of establishing the distances from building structures and other materials below flammability class A2-s1, d0 and the outer surface of the chimney flue.

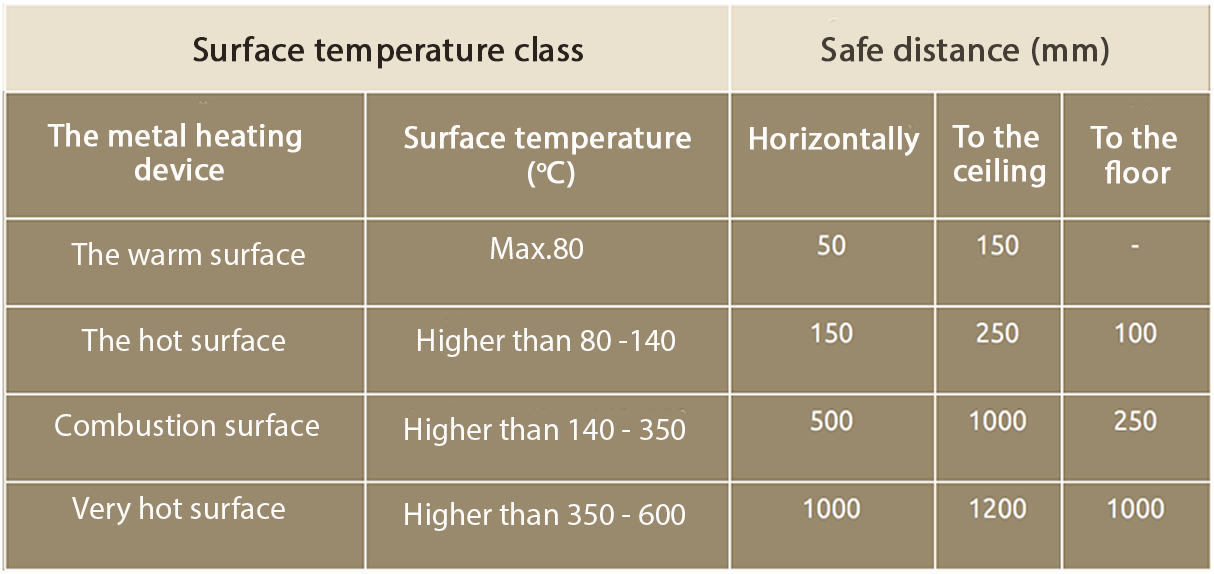

The distances between the metallic heating device and building structures with flammability class lower than A2-s1, d0, and other flammable materials

Table 2

. 5 The principle of protection of walls, partitions and floors around the heating device, surface temperature of which is higher than 80°C,

Fig. 6 The principle of distance determination between the heating device and building constructions and other flammable materials detection principle